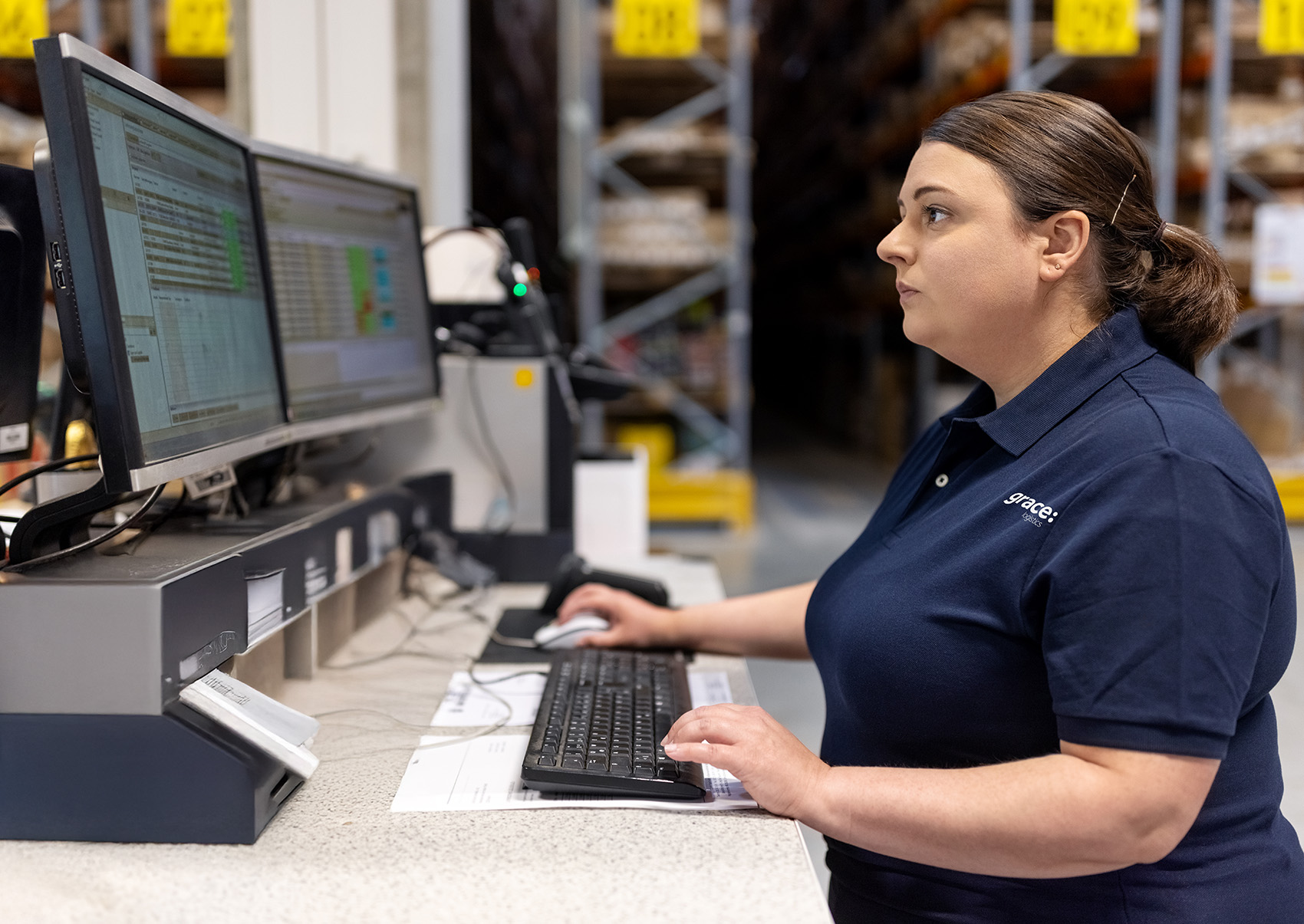

Inventory and systems designed entirely to your needs.

Smarter control of your stock, from dock to doorstep.

Streamline your operations with inventory management tailored to your product mix and growth plans. We optimise processes like receiving, stowing, picking, packing, and stocktaking to reduce touches, boost accuracy, and speed up order dispatch. Using proven warehouse tech like RF scanning, directed picking, and KPI reporting, we enhance efficiency while keeping costs predictable. Gain full track and trace visibility to address issues early and ensure customer satisfaction.

Inventory management shaped to fit.

Whether you sell fashion, cosmetics, healthcare, or luxury goods, workflows are tailored to your range, promotions, and compliance needs, so inventory processes fit your operation, not the other way around.

Goods reception

Upon arrival at our warehouses, pallets are carefully verified against the purchase order, securely unloaded, accurately counted, and thoroughly inspected for quality and condition. Any discrepancies are promptly isolated and reported to ensure swift resolution.

Sorting and addressing

Barcodes are scanned using RF technology to record SKU details, batch numbers, and expiry dates. Once captured, cartons are labeled and strategically stored in optimised locations based on weight, movement frequency, and handling requirements..

Pick and pack management

Pick and pack management streamlines orders into shipments with speed and accuracy. Using RF scanning, optimised slotting, and cartonisation, it reduces travel and packaging waste. Real-time checks on SKU, quantity, and batch/expiry ensure error-free picks.

Packaging and cross docking

Packaging and cross-docking streamline product movement with minimal handling. Inbound cartons are inspected, then re-packed, kitted, or re-labelled as needed to meet customer and retailer requirements. This ensures proper sizing for protection, transport efficiency, and sustainability. The result is a faster, more reliable supply chain process that benefits both businesses and consumers.

Cycle counting and stocktake

Inventory accuracy is regularly checked and variances are quickly resolved by reviewing locations, packaging, and transaction history. Teams make corrections through bin audits or process updates. Together with stocktakes, cycle counts improve accuracy, reduce write-offs, and ensure reliable data for purchasing and replenishment.

Reporting and management

Get real-time control with stock reporting and dashboards. Track inventory, order status, OTIF, aging, and exceptions with alerts. Role-based dashboards monitor KPIs with drill down to bin-level details. Export reports or sync via API to your ERP. Custom widgets, audit trails, and configurable thresholds ensure fast decisions, compliance, and high service levels.

Smarter solutions and leading technology to back it up.

One connected system for all your resources.

Our advanced Grace Compass ERP platform connects warehouse management and distribution with the tools you already use – order management, transport, and eCommerce, via modern APIs and EDI. The result is a single source of truth for inventory positions, batch lot and SKU tracking, FEFO expiry control, and order status across the entire network, accessible in real time through a secure portal and dashboards. This integration improves forecasting and replenishment, streamlines governance and reporting, and eliminates the delays and errors that come from juggling multiple suppliers and systems.